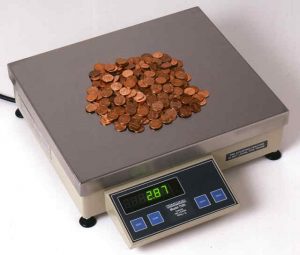

A precision counting scale is a device used to monitor and manage inventories of materials and goods in many industrial environments. The devices are special tools that can quickly and accurately convert weight information into quantifiable data. Counting scales not only display a count of the number of items placed on the scale but also how much each object weighs. Typically found in production facilities, factories, assembly lines, warehouses, and distribution centers, counting scales significantly reduce the time it takes to track inventories manually. In particular, a counting scale is ideal for counting large volumes of small identical parts based on the weight measurement of each part.

Applications for counting scales vary. They can count and weigh items simultaneously. For check weighing, counting scales can be used to check the weight of items against a preset limit to perform accurate parts counting before manually counting. They can also be used to weigh samples of uniform items to calculate the average weight of each piece and then accurately determine a total count based on that weight.

How Counting Scales Work

As the name suggests, counting scales utilize weight to count the number of pieces in a given lot. It is done by entering a sample weight of an item from the lot and then dividing the total weight of the lot by the weight of the sample. In other words, by dividing the weight by the number of pieces entered on the scale, the scale computes the average piece weight (APW) to produce a count. Because counting works by the weight of an object, the objects being weighed must be uniform to get an accurate count. You cannot mix different items of different weights on the scale. For example, you can’t weigh screws and bolts simultaneously and get an accurate count. An accurate count is only assured by weighing identical items that have the same weight.

What to Look For

When shopping for a counting scale, consider important features such as its counting function, interfaces (RS 232 serial or USB), numeric keypad, rechargeable battery power, audible alarm, removable stainless steel platform, programmable, legal for trade, and printing capabilities. Look for scales with three displays to track unit weight, tare weight, piece count, and total weight, and models that meet your inventory’s capacity and accuracy requirements. For example, a scale with a larger platform size and tare feature is more for efficient check counting of large quantities. A 50-pound capacity counting scale is not the ideal choice when counting no more than 10 lbs of parts at a time.

Benefits of a Counting Scale

Precision counting scales offer several benefits in the inventory management of parts and components used in manufacturing and production. Accurate inventory counts allow companies to make informed operational decisions. They build consumer confidence by ensuring that goods ordered by customers are accurately counted and that the customer receives the correct number of units as ordered every time. For quality control purposes, knowing the accurate weight data of a product also allows companies to identify irregular-sized components during production. With counting scales, companies can accurately check inventory for the number of pieces in a lot. For large inventories of a particular item, counting scales can be used to create lots for easier tracking and counting of inventories.

Accuracy is vital for companies to manage their supply chains effectively when counting thousands of pieces or parts. Ideal for quality control centers, retail warehouses, production facilities, and factory environments, precision counting scales provide the most efficient, reliable, and cost-effective method of accurately counting and tracking large quantities of inventory in real time. For more information on how your company can save time and money while counting small parts more efficiently and accurately, contact Worcester Scale Company today.

Leave a Reply