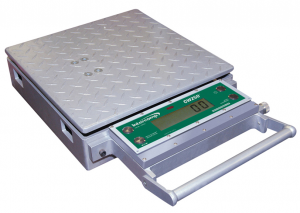

Digital platform scales are electronic instruments that offer precise and accurate measurements of goods and products in an industry. Accurately weighing products is essential to production, compliance, and profitability in nearly all processing and manufacturing environments, as well as transportation, shipping, and logistics.

Digital platform scales are electronic instruments that offer precise and accurate measurements of goods and products in an industry. Accurately weighing products is essential to production, compliance, and profitability in nearly all processing and manufacturing environments, as well as transportation, shipping, and logistics.

Because weight management is essential in various industries, precision weighing systems are vital for companies. Where mechanical platform scales once provided managers with limited weight management options, advancements in technology now offer precision and accuracy once unobtainable. Today, digital platform scales provide cost-effective solutions and ensure consistency, detail, and efficiency for companies that mechanical scales cannot attain.

Digital Platform Scales: Why Accuracy Matters

In the industrial world, weight is a valued commodity. Managing it effectively can give companies a competitive edge. Accurate weight readings and measurements are as much a part of a company’s underlying success as an inaccurate system can lead to its failure.

Precision weighing systems provide the necessary information and data to successfully guide companies’ financial, logistical, operational, and regulatory decision-making. The processing of foods, beverages, pharmaceuticals, and chemicals relies on calculations derived from accurate weight management, as do supply chain processing—the transportation, shipping, and receiving of goods—and the agriculture, automotive, aerospace, construction, engineering, and mining industries, and so on.

Companies depend on accurate weight management systems to remain profitable. Choosing digital scales over mechanical scales provides an advantage to companies and allows technology to build on the margins that keep them competitive and profitable. There are simply too many limitations for one over the other not to consider a digital weight management solution.

Limits of Mechanical Platform Scales

A mechanical platform scale is an analog balance device used to measure the weight of objects without the need for a power supply. To operate, the system is composed of an understructure of pivots and bearings and moving parts such as lever arms, hangers, couplings, and linkages that are either connected to a spring dial or sliding weight arm.

Compared to digital scales, mechanical scales are limited in accuracy and precision. Over time, parts age and become worn out; accumulation of dust, dirt, and debris within the scale mechanism can lead to friction errors; and inadvertent shock loading of scales subject bearing surfaces to deformation, all of which can lead to imprecise and inaccurate weight readings.

Operator errors compound mechanical limitations. When reading a sliding arm or dial scale, the measurement readouts are based on gauged increments subjected to the scale operator’s view and angle. No matter how careful scale operators are, the system is prone to inconsistent readings. Add to this first the measurements that must be written down, and then perform calculations such as converting pounds to kilograms or subtracting the tare weight from the gross weight to prepare the bill of laden. With each step, the chance of human error increases, and your company’s competitive edge dulls and decreases.

Advantages of Digital Platform Scales

In any industrial process, collecting and analyzing data is essential to maximize efficiency and eliminate waste. Reliable and consistently accurate readings are the basis for an efficient lean weight management system. Such a critical role rests on utilizing a precision weighing system that minimizes all risk and performs to its full extent. The only risk associated with digital platform scales is that they depend on a power source for operation.

Otherwise, digital platform scales are not only superior to mechanical scales but also the optimal precision weighing system. They are a completely automated system that greatly reduces, if not entirely eliminates, the chance for human error. Other advantages include:

- Advanced, highly accurate electronic load cells for precise readings.

- Large, brilliant LCD screen for easy viewing of measurements.

- Onboard intelligence with programmed math functions and data analysis.

- Data transfer capability to computers or storage devices for further analysis.

- Networking capabilities for in-person touch screen or remote operation.

Contact the Scale Professionals Today

Digital platform scales offer significant advantages over mechanical systems. Accuracy afforded by digital scales provides consistent, reliable readings to ensure the data you receive improves production and reduces waste. If weight management is critical in your company, digital platform scales are the most productive, cost-effective weighing solution. To learn more about our products, please contact us at Worcester Scale today.

Leave a Reply