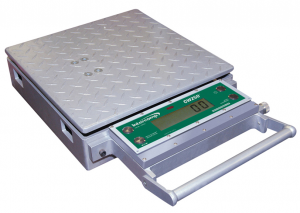

A key component to any weighing system or set of commercial scales is the weighing scale display screens that provide operators with the necessary data and information about their industry’s weight measurement. Scale display screens come in various types, each with its own unique characteristics and advantages.

Types of screens can vary depending on several factors and the specific needs or requirements of the commercial or industrial weighing operation at hand. The three leading display types used in weighing system applications or with commercial scales are the digital LCD, touch screen, and graphic display. Here’s what distinguishes one from the other and the applications they are suited for:

Digital LCD Display Screen

Digital LCD (Liquid Crystal Display) screens are the most common display component for electronic weighing scales. They are regarded for their clarity, readability, and adaptability with many devices. LCDs are a cost-effective option, too. They feature backlighting for easy reading in low-light conditions, and many have connectivity options like Wi-Fi to sync data with smartphones or other devices.

As letters and numbers are formed from limited shapes, LCD screens have more limited display capabilities than touch screen or graphic displays, but they’re still highly effective, providing users with precise and easily readable weight information. LCD screens typically display numerical values representing the weight measurement in various units—pounds, kilograms, or ounces—depending on the scale’s settings.

LCD weighing scale display screens are used in various applications requiring weight measurement and display. They are often used with retail and commercial scales, with industrial scales in factories, warehouses, shipping, and production facilities, precision scales used in laboratories, with medical and health-related scales, for weight readouts in mining and construction materials and equipment, and transportation and logistics hubs for determining the weight of vehicles and their loads.

Touch Screen Display Screen

As the name suggests, touchscreen displays incorporate a digital interface that responds to touch rather than physical buttons or keys. Known for their versatility, users interact with the display by simply tapping, swiping, or entering numerical data directly on the screen. These displays can show various kinds of information, including weight measurement, totals, tare weight, and more, all on a single screen.

Touch screen displays allow for user-friendly, often intuitive, interactions and include features for users to navigate different scale functions. For example, data logging capabilities are, literally, at the touch of a finger, allowing users to record and store weight measurements for future reference or analysis. Customized setting features enable users to configure the display layout, units of measurement, and other settings to suit their specific application needs. Depending on the scale’s features, touchscreen displays may have connectivity options for USB or Wi-Fi to enable data transfer to other devices or systems for further processing, inventory control, and analysis.

Such scales are commonly used in various industries, including industrial and manufacturing, shipping, warehouse and logistics, medical, healthcare and pharmaceuticals, laboratory and scientific, and agricultural, where precise and accurate weight measurements are required.

Graphic Display Screen

Graphic display screens are specialized electronic screens or monitors used with a weighing system or balance, sometimes called a weight indicator display or scale display. Graphic display screens are designed to display weight-related information in a user-friendly and easily readable format. In other words, these screens provide visual feedback for users and operators, making reading and interpreting weight-related information easier.

Unlike touch screens, graphic displays provide easy-to-use, menu-driven options and navigation via the touch of a button. This feature is especially useful in laboratory, medical and healthcare, pharmaceutical, and food and beverage environments where gloves are necessary and would otherwise interfere with a touch response.

Menu-driven features at the touch of a button allow users to scroll through and select choices on the instrument panel easily. Weight is displayed in numerical values in various units such as kilograms, pounds, grams, ounces, etc., and, depending on the display capabilities, can offer graphical representations of weight data, such as bar graphs, pie charts, or other visual indicators, to provide users with a more intuitive understanding of the weight being measured.

These screens are commonly found in various industries and applications, including manufacturing, agriculture, retail, healthcare, laboratories, transportation, and more. Their primary purpose is to provide users and operators with accurate, easily readable visual feedback of weight information to support efficient and precise measurement processes.

Contact the Experts at Worcester Scale Company

Overall, weigh scale display screens are pivotal in providing industries with accurate and easy-to-read weight measurements. The features and complexity of the display can vary depending on the type and purpose of the scale. Worcester Scale Company offers a complete line of electronic scales and can help ensure you use the weighing scale display screen best suited for your applications. For over 70 years, we have provided our customers with affordable and effective weighing solutions. Contact us today for more information on weighing scale display screens for your weighing systems and commercial scales.